PRODUCTION CAPACITY

24/7 Continuous operation

Production process is optimized by reducing production cycle interruptions

Industry 4.0 ready

24/7 Continuous operation

Production process is optimized by reducing production cycle interruptions

Industry 4.0 ready

Product quality improvement thanks to the highest precision and accuracy from part to part in every single operation.

Shorter delivery time and improved production capacities

Better performance results in competitive advantage

Cost of labor reduction

Accident rate reduction

Production scraps reduction

And many other industries where production lines move big batches of the same goods.

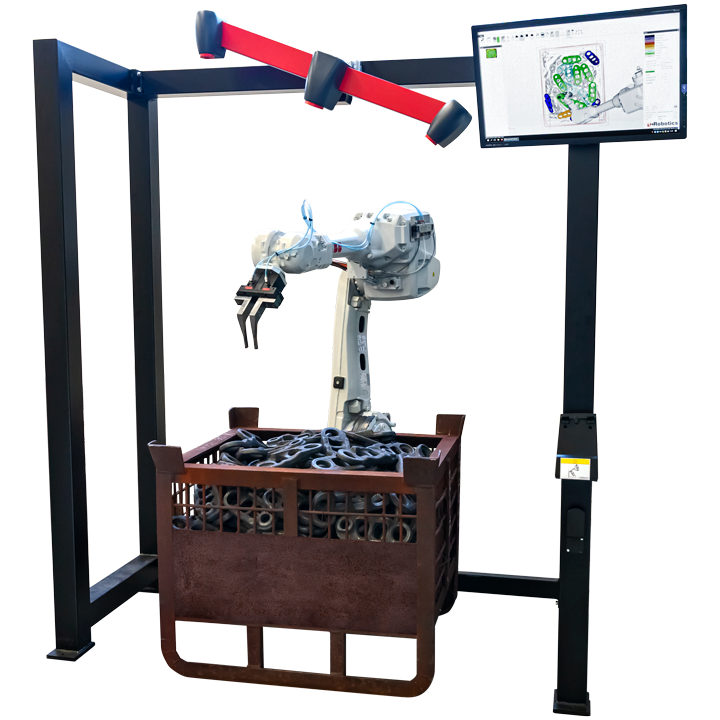

The 3D vision system for random bin-picking enables any robotic manipulator to collect randomly arranged objects inside a container.

For further information and request for quote please contact us.