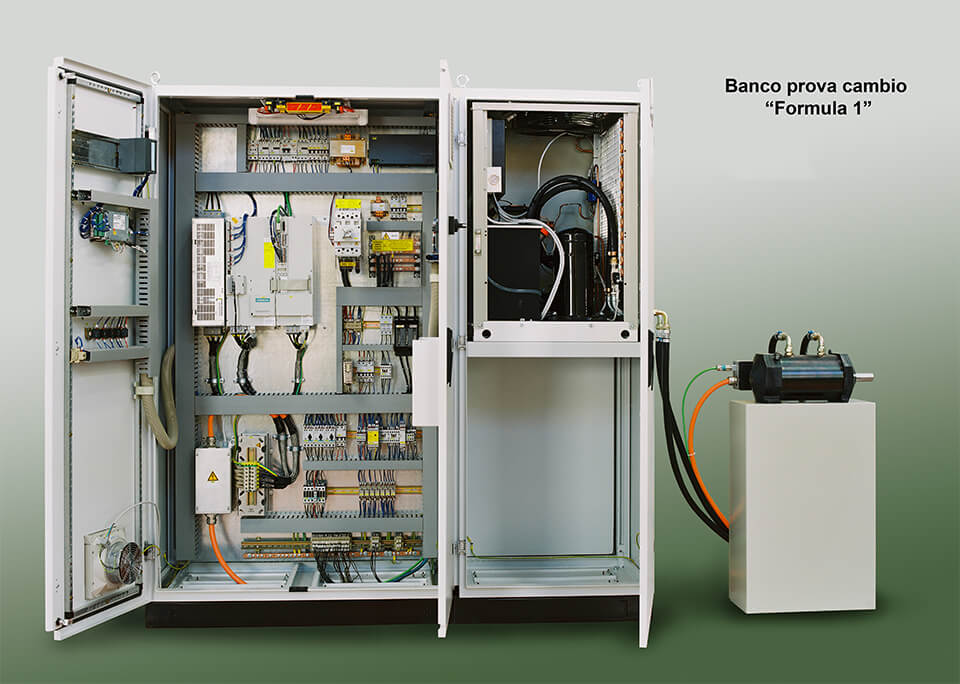

Project Group applies special equipment to standard machines in order to improve production efficiency. Automatic loading, testing and quality control of such machines ensures that finished parts (benches), semi-finished products or assembled components are all up to date, including:

- Control and inspection of assembly stages

- Functional tests, measurements of fundamental quantities, data acquisition

- Data storage on a database, traceability and report generation.